Outside Plant (OSP) Fiber Optic Scope of Work

1. Survey & Design

Route survey and site walkouts.

Identification of obstacles (roads, railways, utilities, bridges).

Preparation of detailed design drawings and shop drawings.

Route approvals and Right-of-Way (ROW) coordination with authorities.

2. Civil Works

Trenching & Excavation

Standard trenches with sand bedding and backfilling.

HDD (Horizontal Directional Drilling) under roads, rivers, and hard surfaces.

Duct Bank Installation

HDPE ducts, sub-ducts, and micro-ducts.

Sealing, mandrel testing, and pulling rope installation.

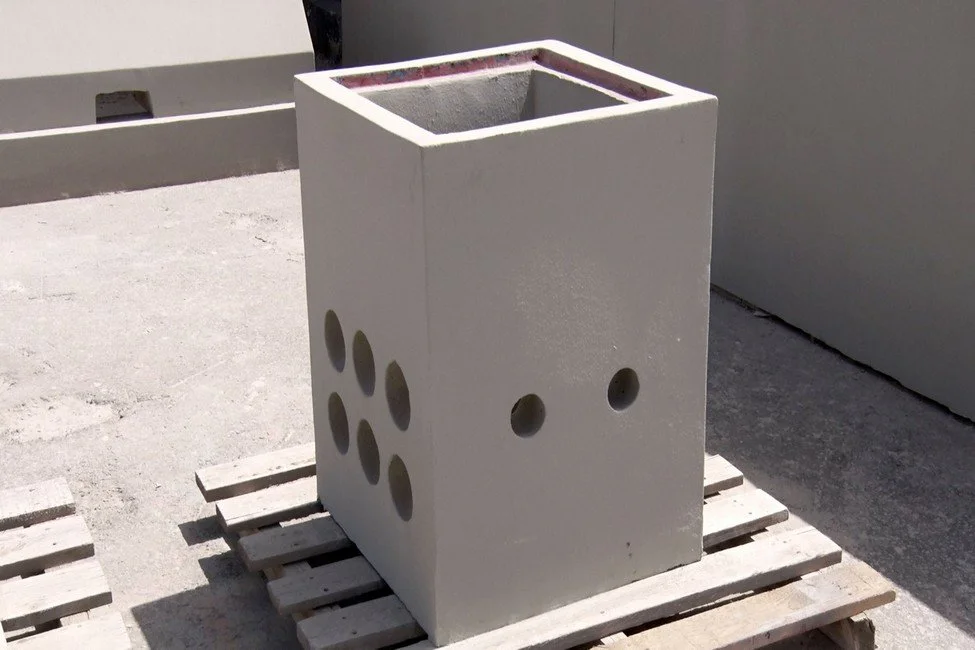

Manholes & Handholes

Construction and installation of fiber chambers.

Placement of joint boxes, splice enclosures, and marker posts.

3. Cable Installation

Laying of fiber optic backbone cables (singlemode OS2).

Blowing, pulling, or jetting of cables into ducts.

Armored or dielectric cable installation depending on soil conditions.

Aerial installation (if applicable): pole-mounted fiber, ADSS cables.

4. Splicing & Termination

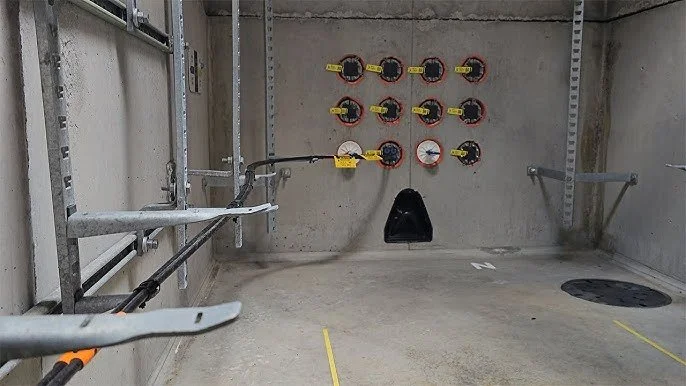

Fiber splicing in manholes/handholes.

Termination at Optical Distribution Frames (ODF) at datacenter/POP entry.

Splice closures, protection sleeves, and proper slack storage.

Labeling of all splices and termination points.

5. Testing & Acceptance

OTDR Testing at 1310/1550 nm.

Power Meter & Light Source Testing for insertion loss.

Continuity Checks (visual fault locator).

End-to-end test reports for each fiber core.

6. Documentation & Handover

As-built drawings with route maps and manhole locations.

Fiber allocation sheets (core assignment).

OTDR traces, loss test reports, and continuity results.

Route markers and labeling of manholes/handholes.

O&M manual and maintenance guidelines.