Cable Pathway Infrastructure

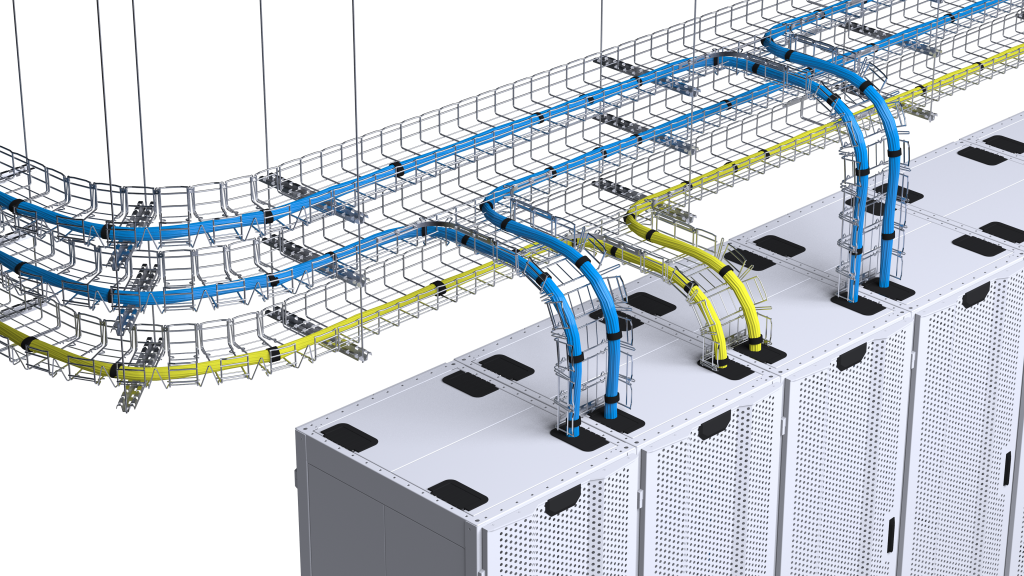

Overhead Containment Systems

Ladder racks, basket trays, and fiber runners for main distribution.

Separate containment for fiber and copper to avoid interference.

Suspended and seismic-rated supports.

Underfloor Systems (if raised floor is used)

Conduits, sub-floor trays, and ducts for power/data segregation.

Grommets with brush seals for airflow containment.

Vertical Pathways

Riser ducts, wall conduits, and vertical managers between floors.

Rack-Level Cable Management

Horizontal Cable Managers

Single and dual-sided cable managers with finger ducts.

Brush panels for patch cord routing.

Vertical Cable Managers

High-capacity vertical managers alongside racks.

Cable spools, D-rings, and management loops.

Rear Rack Cable Routing

Proper dressing of patch cords, secured with Velcro straps (no zip ties).

Fiber slack storage trays.

Fiber Management

Fiber Raceway Systems (Panduit, CommScope, or equivalent).

Yellow ducting systems dedicated for optical fiber.

Bend radius control fittings, tees, elbows, and drop-outs.

Patch Panels & ODFs

Modular ODFs with LC/SC/MTP cassettes.

Sliding drawers for easy access and maintenance.

Standards Compliance

Minimum bend radius: 10× cable diameter (TIA/EIA-568).

Separation from copper and power cables.

Copper Management

Structured Cabling

Category 6A/7 cabling for horizontal and backbone links.

Patch panels with integrated management.

Pathways

Routed separately from fiber raceways.

Patch cords dressed to avoid strain on jacks.